Degradation vs Contamination

Your thermal fluid system has been operating flawlessly for many years. Now, all of a sudden, you are noticing symptoms that are impacting your operations. It could be that your batch times are taking longer, pump seals are failing, the expansion tank is overflowing, or any number of signs that tell you something is wrong with the quality of your heat transfer fluid. The reality is that just like the oil in your car engine, thermal fluids will degrade and require filtration, venting, and fluid replacements over time.

If you have a routine fluid testing program it is highly unlikely that sudden changes in operational symptoms would be the result of age-related fluid degradation. This is because any changes in the fluid’s physical properties would show up in the regular fluid test results over time and give you plenty of opportunities to make corrections long before impacting your operations. In most cases, a rapid change in fluid quality is more likely due to the impact of a recent event such as an operational change, a system modification, or accidental contamination of the fluid.

SO, WHAT IS DEGRADATION ANYWAY?

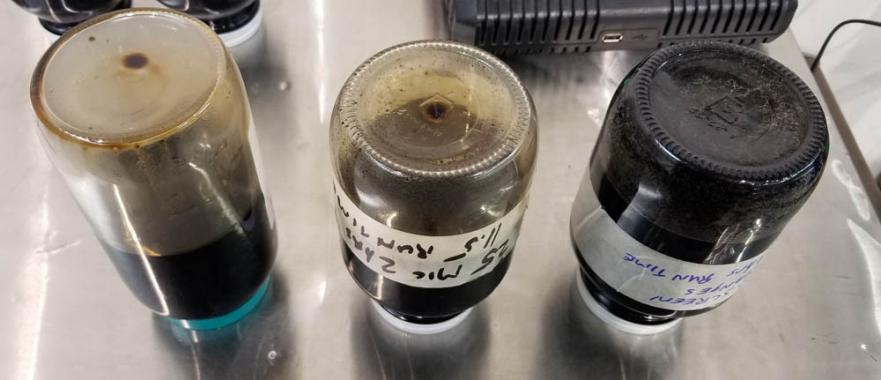

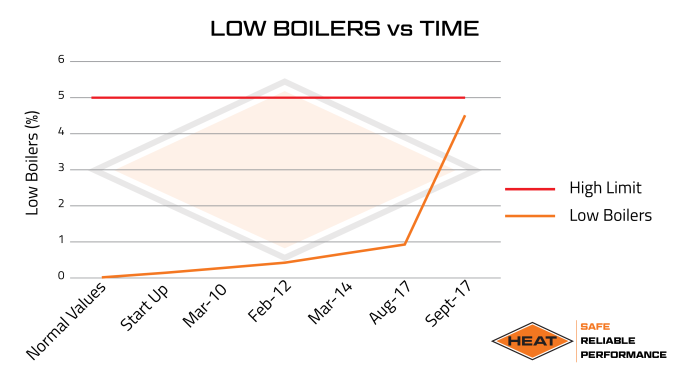

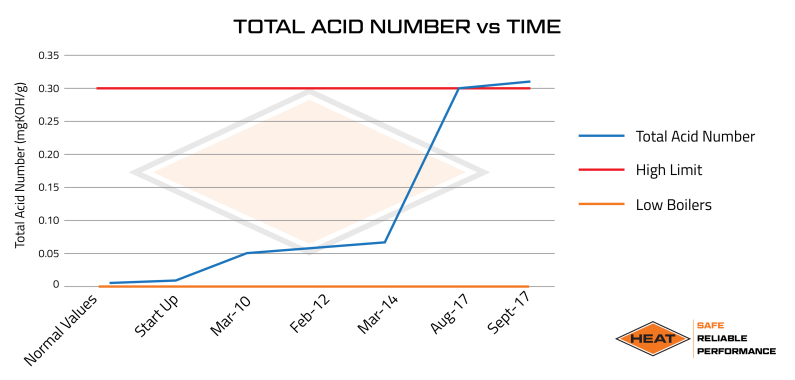

Degradation is when the individual molecules of the fluid begin to break down. Essentially, the molecules will either break apart into various sub-components or they will form new compounds that exhibit undesirable characteristics and altered physical properties compared to the original heat transfer fluid. Some of the new components of the fluid will be lighter fractions (often called: low boilers or light ends); other constituent components will form heavier compounds such as high boilers, sludge, and insoluble solids. Normally, heat transfer fluids are designed to be durable, and the molecules will remain stable for many years. Unfortunately, these fluids are also operating under harsh conditions.

Degradation cannot be eliminated; it can only be slowed down through careful fluid stewardship and proper maintenance of the fluid. Fluid degradation is caused primarily through three types of reactions. The first type of reaction is a thermal reaction, where individual molecules of the fluid are being exposed to surface (film) temperatures that are higher than the molecule can tolerate. The second type is an oxidation reaction where the fluid is being exposed to oxygen at high temperatures which forms organic acids and eventually reacts to form various types of solids. The third type of reaction is due to the introduction of foreign contamination into the fluid which can result in a wide range of new compounds depending on the nature of the contamination.

HOW CAN I TELL IF MY FLUID IS DEGRADED OR CONTAMINATED?

The simple answer: Routine testing. The most effective way to tell if degradation reactions are taking place in your fluid is through routine testing of the fluid for its physical properties. Standard physical properties tests such as viscosity, density, specific heat, and thermal conductivity should be performed. But the most important tests to perform are the Acid Number and the Distillation Range. These results will point to the type of degradation that is occurring.

Much like how a doctor interprets blood test results, fluid test results will indicate when and how degradation is occurring. Some combinations of test results will let you know that you have an oxidation problem. Other combinations will show if the fluid is thermally stressed or if the fluid requires additional venting or even less venting. And finally, they can indicate when the fluid has been contaminated with water or your product or some other foreign materials.

Regular tests of your thermal fluid will keep you informed about its health, and alert you to preventative maintenance that can be performed before your process needs to be shut down.

The best way to take a hot oil sample:

Contact Customer Service

Phone: 412-276-3388

Fax: 412-276-3397