Heating Gases

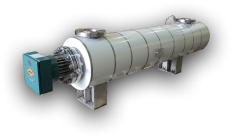

These self-contained electric heating units are designed to heat a wide range of flowing gases. Heaters can be installed vertically or horizontally. Each heating unit consists of a tubular flanged heater mounted in a steel or alloy pressure vessel. The vessel is equipped with inlet and outlet pipe connections, air bleed, drain, mounting lugs, high temperature insulation with protective metal jacketing. Circulation heaters are available in a wide range of kW sizes, construction materials, NEMA ratings, controls and other options.

Electric Gas Heaters work in much the same way as heat exchangers, but with electric heating elements for the heated surface area. The flowing gas is directed across the electric heater elements to increase the temperature of the gas. High pressure gas heaters have elements contained inside of pressure vessels. Low pressure gas heaters have elements contained inside of duct work. Electronic temperature controllers are used to provide extremely accurate control.

Gas Circulation Heaters and Duct Heaters can be designed for heating a wide range of flowing gases such as: Air, steam, nitrogen, natural gas, and other process gases.

Proper design of a Gas Heater will need to take the following data into consideration:

- Flow rate and properties of gas to be heated

- Temperature and pressure of the gas

- Process and installation parameters

The heat systems below provide direct temperature control of gases.

CLICK ON A SYSTEM FOR MORE INFORMATION ON DESIGN TEMPERATURES AND PRODUCT FEATURES TO MEET YOUR PROCESS REQUIREMENTSContact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.