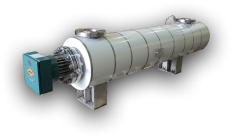

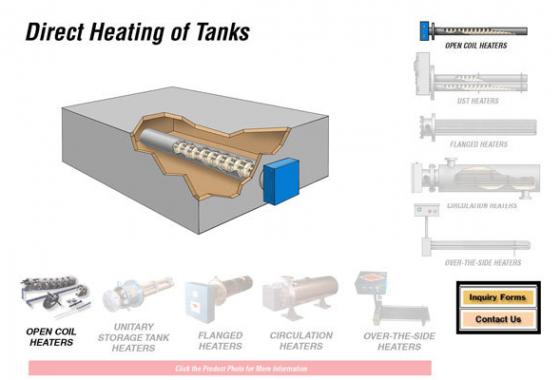

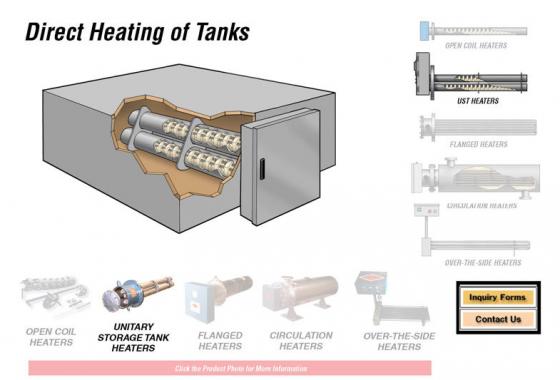

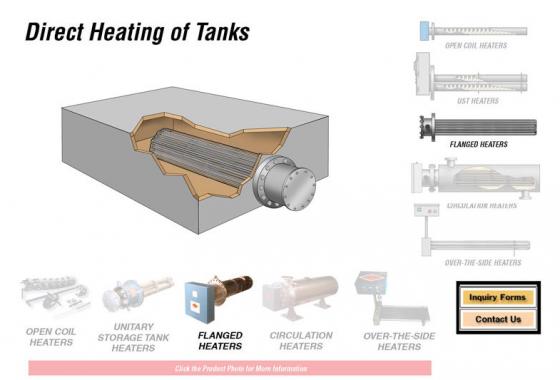

Direct Heating of Tanks

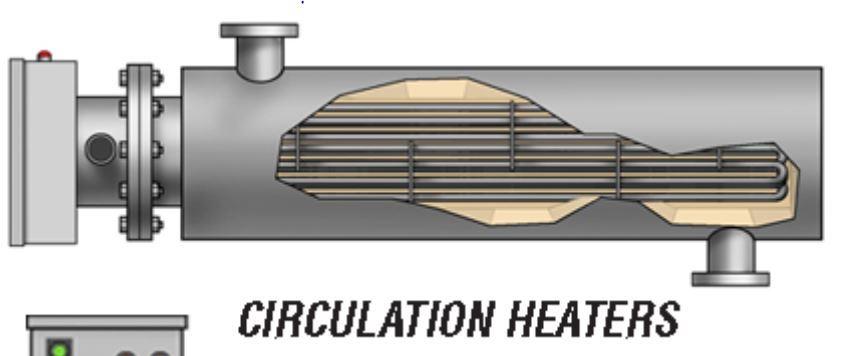

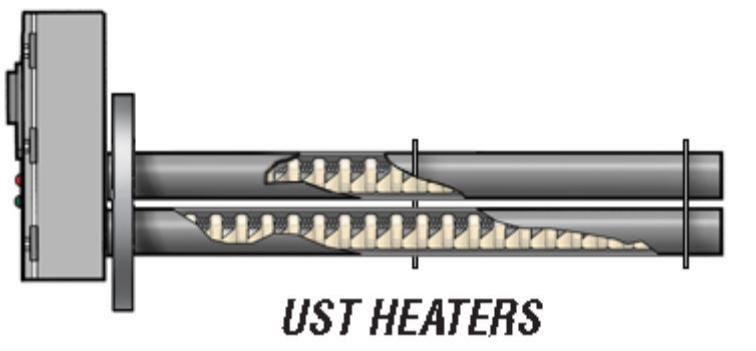

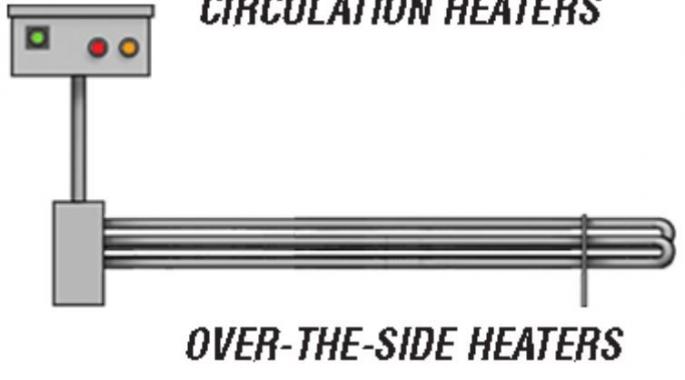

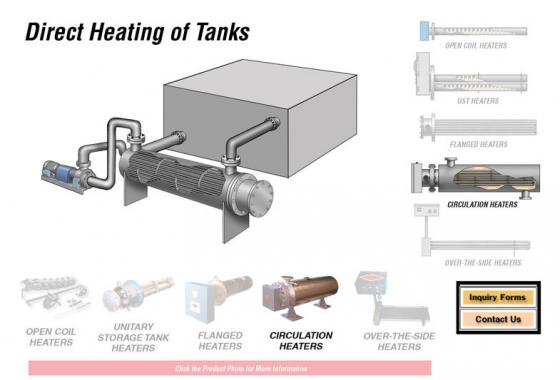

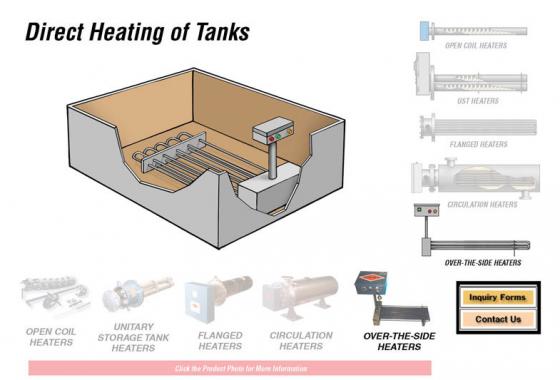

The most common and most efficient method of heating tanks is to directly heat the tank contents with an electric immersion heater. Nearly 100% of the electrical energy used by the heater is absorbed by the product inside of the tank. A well-insulated tank requires very little energy to maintain tank temperatures. A variety of heater elements can be utilized depending on the tank design, temperature range and heat sensitivity of the product to be heated. Some elements are installed through openings in the top of the tank and others are installed through nozzles in the side of the tank. Large tanks often utilize elements inside of closed pipe wells to eliminate the need to drain the tank for replacement. When direct immersion is not practical, the fluid can also be pumped through an external heater and returned to the tank.

Nearly every liquid storage tank can utilize a direct electric heater element. Common applications include: water and oil storage tanks, chemical tank farms, railroad terminals, hydraulic reservoirs and pipeline terminals. New tanks have almost limitless options for installation, while existing tanks may require special customized installations.

Properly designing a tank heater requires the following information:

- Properties of the material to be heated

- Detailed drawing of the tank with insulation specs

- Quantity and size of available connection ports

- Size of the heater is based on the volume of the tank and the heat up time required

The heat systems below provide direct temperature control of various types of tanks and vessels.

CLICK ON A SYSTEM FOR MORE INFORMATION ON DESIGN TEMPERATURES AND PRODUCT FEATURES TO MEET YOUR PROCESS REQUIREMENTSAdditional Methods of Direct Heating of Tanks

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.