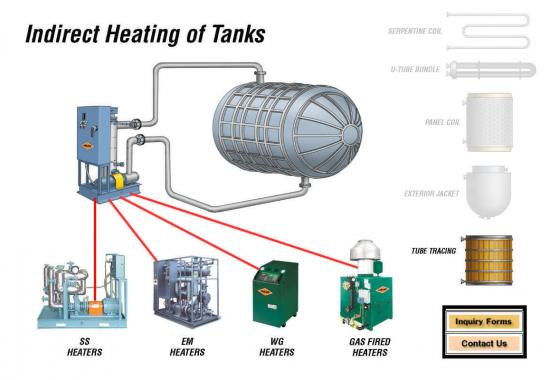

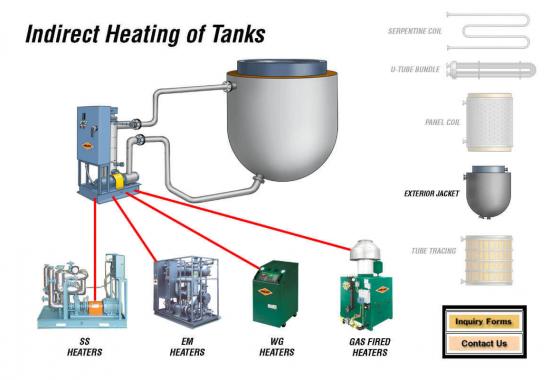

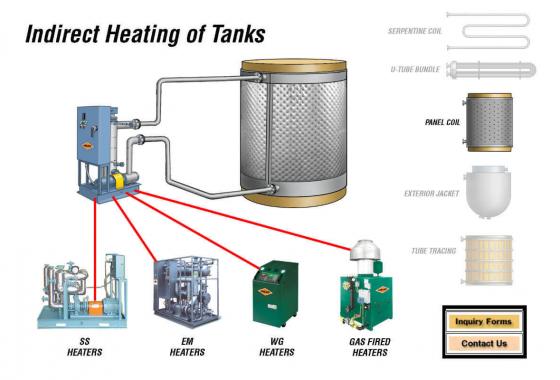

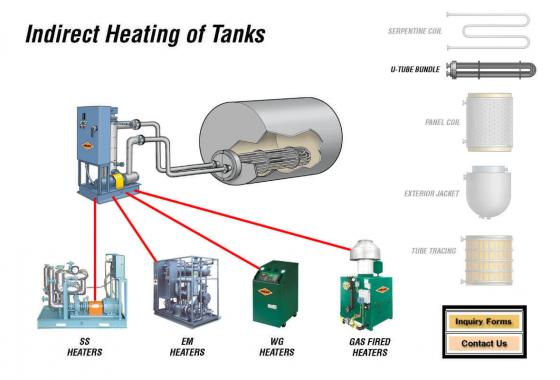

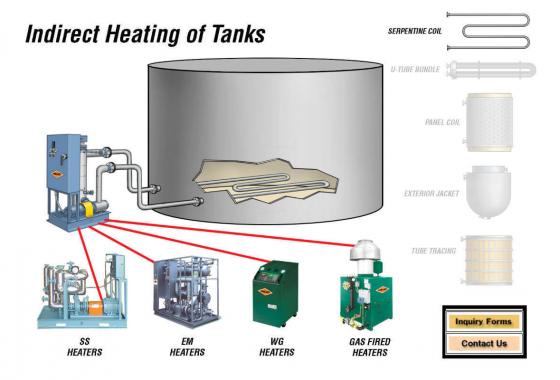

Indirect Heating of Tanks

One of the most accurate and efficient methods of Tank Temperature Control is to circulate a fluid media through a heat transfer coil or jacket. A single fluid can be used to provide both heating and cooling as required to control the temperature of the tank contents. Depending on temperature range, these fluids can be water, glycol mixtures, or heat transfer oils. Circulating heat transfer systems can be equipped with independent heating and cooling capacity or they can be tied into existing plant central heating and cooling utilities. Tanks can be equipped with either internal or external coils in a variety of configurations and installation methods.

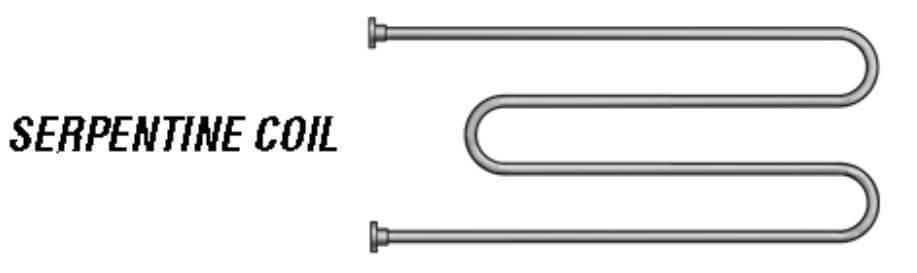

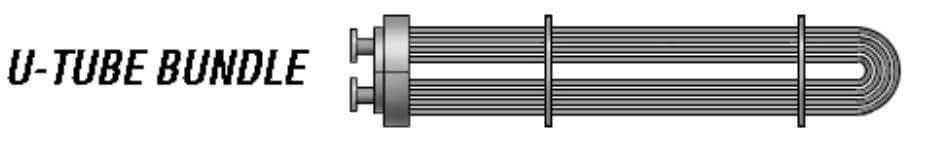

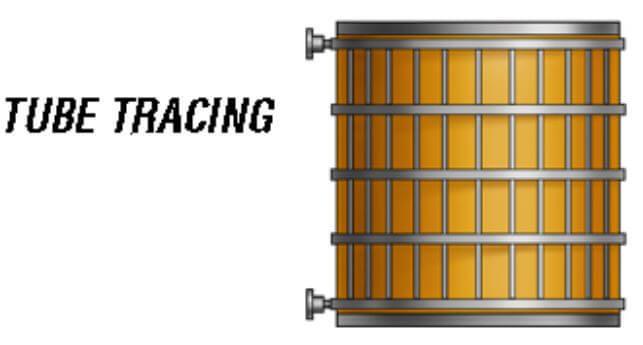

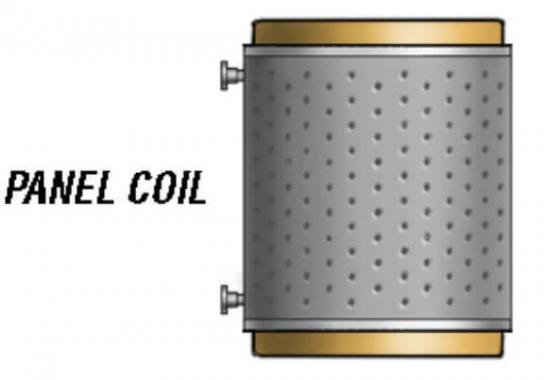

Nearly every liquid storage tank can utilize indirect heating and cooling temperature control. Common applications include: large water and oil storage tanks, chemical tank farms, railroad terminals and pipeline terminals. New tanks are typically equipped with serpentine pipe coils or U tube coils. Existing tanks can be equipped with external bolt-on panel jackets or tube tracing.

Properly designing a heat transfer system for the indirect temperature control of tanks requires the following information:

- Jacket or coil detail; the pump must be sized based on the design of the flow paths

- Detailed drawing of the tank is very helpful

- Quantity and size of connection ports will help determine maximum flow capacity

- Heater size is based on the volume of the tank or vessel in addition to the desired heat-up time

The heat systems below provide indirect temperature control of various types of tanks and vessels

CLICK ON A SYSTEM FOR MORE INFORMATION ON DESIGN TEMPERATURES AND PRODUCT FEATURES TO MEET YOUR PROCESS REQUIREMENTSContact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.