Thermal Fluid Systems for Mining, Metals, & Minerals

The Mining, Metals, & Minerals Market demands highly durable, long-lasting performance to meet constant production demands. Equipment must be rugged as it operates in extreme environments surrounded by high temperatures, molten metals, and large forces.

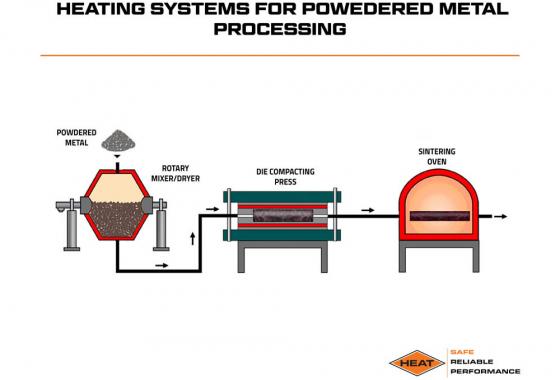

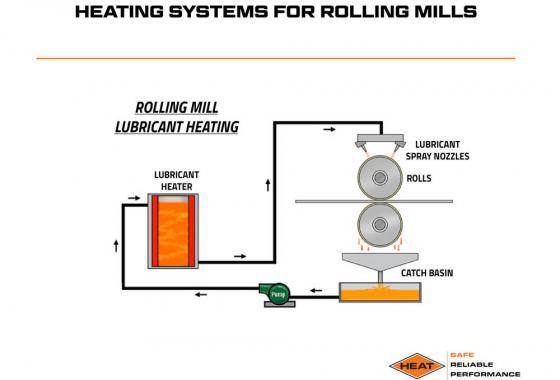

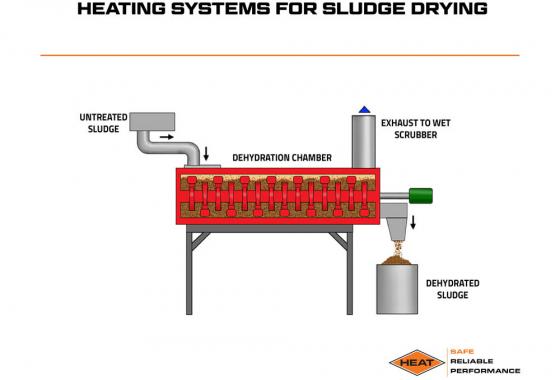

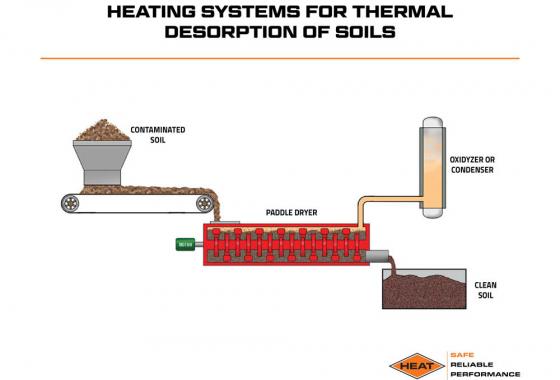

Downtime from equipment means efficiency losses — lost time is lost money in this industry more than almost any other. Temperature control equipment must be durable and give long-lasting performance. HEAT has frequent experience working with our customers in this industry to develop unique temperature control solutions that deliver our signature Safe Reliable Performance. Our experience includes designing custom solutions for these applications:

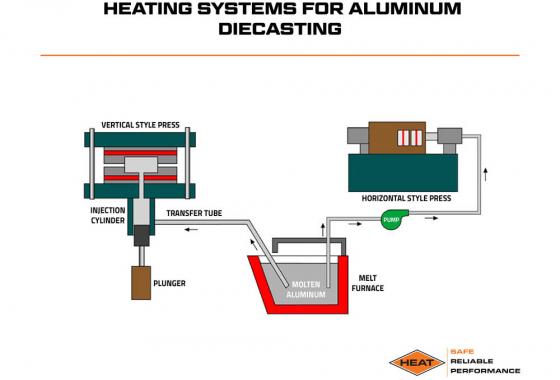

- Aluminum Die Casting

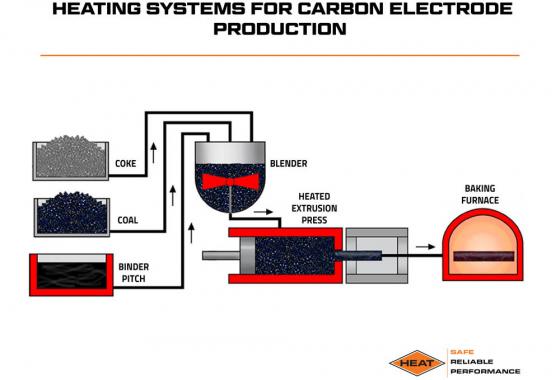

- Carbon Electrode Production

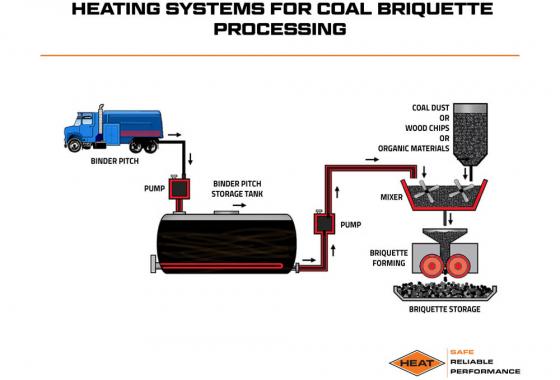

- Charcoal Briquette Processing

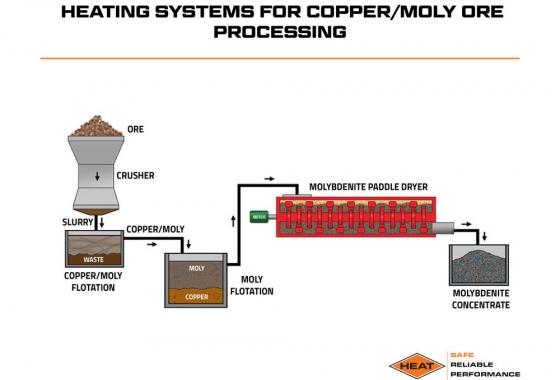

- Metals & Ore Processing

- Rolling Mills

- Sludge Drying

- Thermal Desorption of Soils

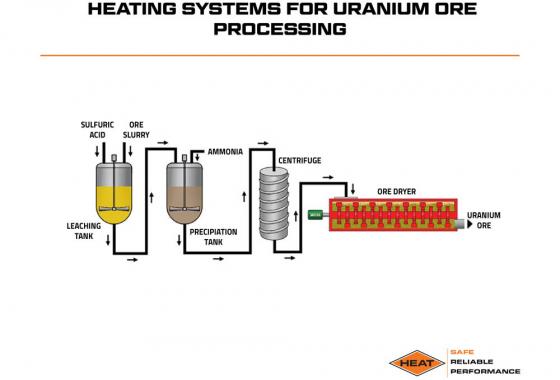

- Uranium Ore Processing

Contact us today to request your custom temperature control solution or scroll through the application gallery below to learn more about our expertise.

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.