Thermal Fluid Systems for Power, Energy, Oil & Gas

Temperature Control is a critical component of the energy industry, helping to make sure that energy production and transportation is both safe and efficient. Steam needs to be at the correct temperature to spin a turbine generator, crude oil must be at the right temperature to be processed into fuel, and chemicals must be kept at certain temperatures to avoid dangerous reactions. It is imperative that equipment be extremely safe and durable.

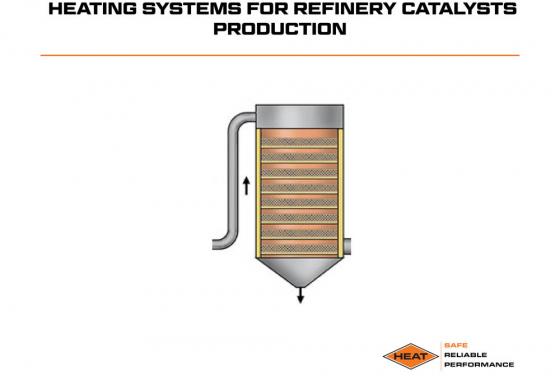

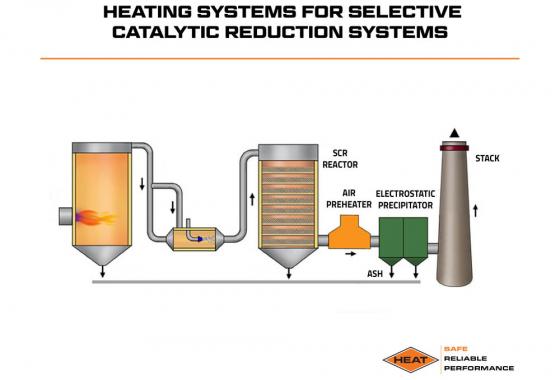

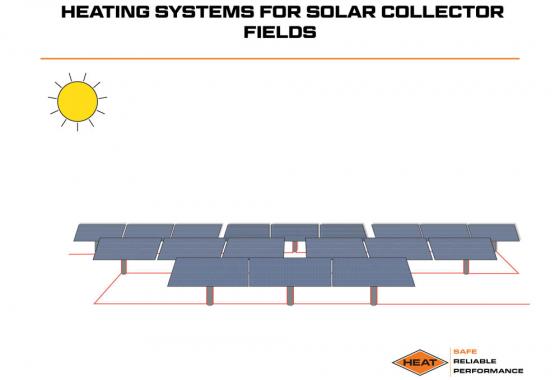

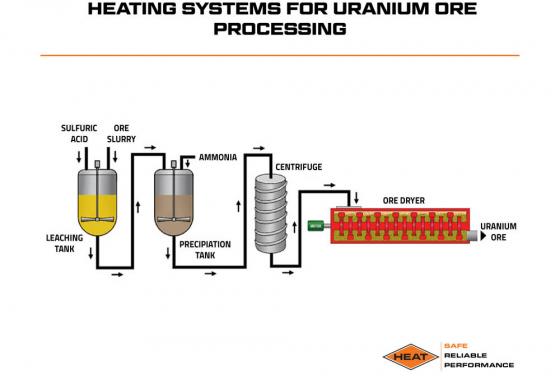

HEAT has extensive experience manufacturing custom systems that are code compliant to meet the safety regulations of this industry, delivering you the safe reliable performance our brand is known for. Our experience includes designing custom solutions for these applications:

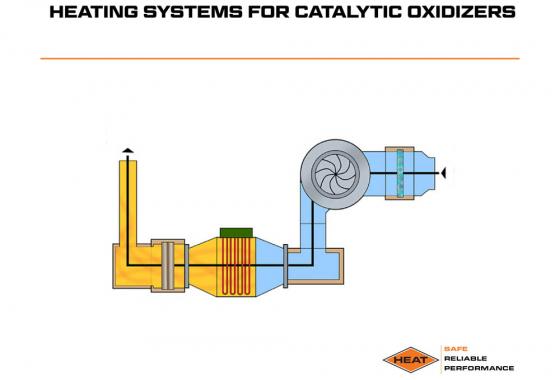

- Catalytic Oxidizers

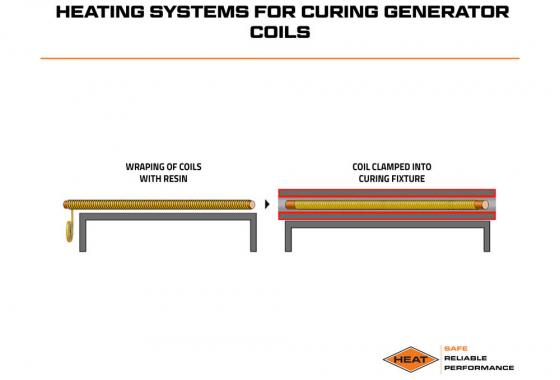

- Generator Coil Curing

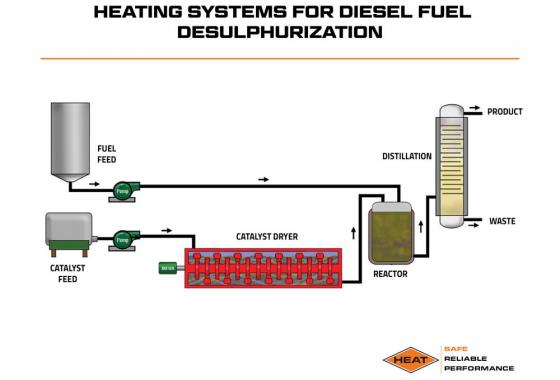

- Diesel Fuel Desulphurization

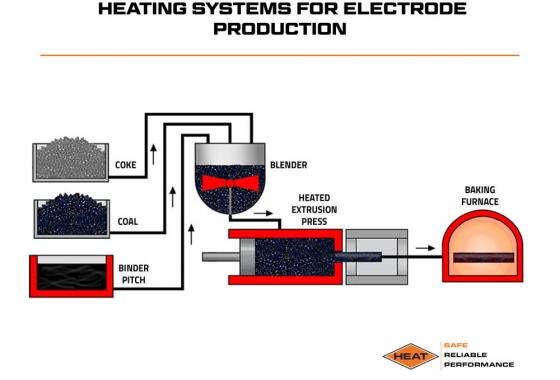

- Electrode Production

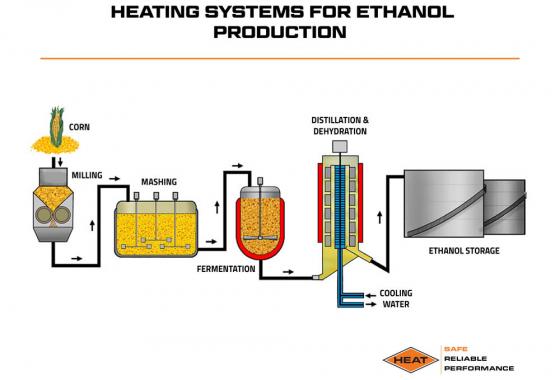

- Ethanol Production

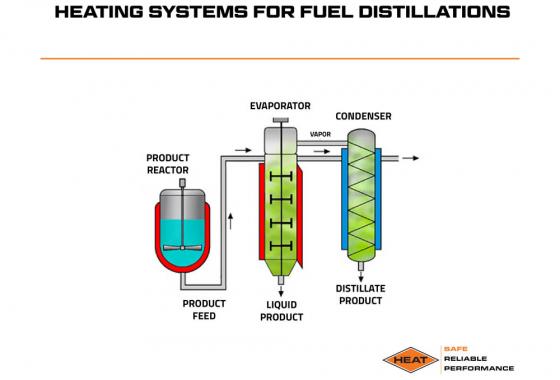

- Fuel Distillation

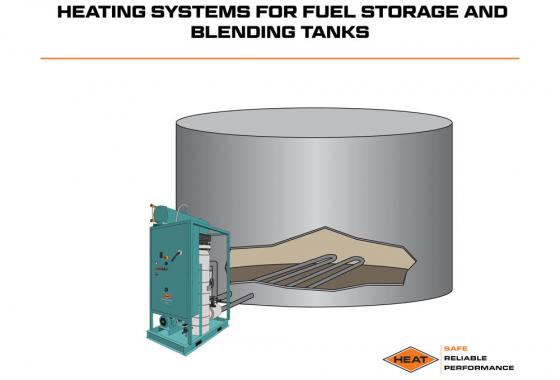

- Storage & Blending Tank Heating

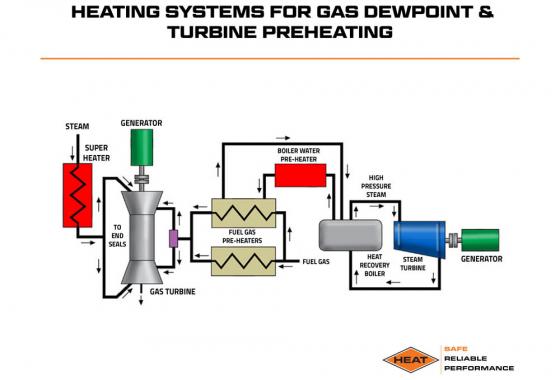

- Gas Dewpoint & Turbine Preheating

- Refinery Catalyst Production

- Catalytic Reduction Systems

- Solar Collector Field Heating

- Uranium Ore Processing

Contact us today to request your custom temperature control solution or scroll through the application gallery below to learn more about our expertise

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.