Pre-Engineered & Custom Expansion Tanks and Vessels

Expansion Tanks and Vessels are critical parts of a heat transfer system. Properly designed and installed tanks can avoid many system complications such as: low fluid level, fluid expansion, Net Positive Suction Head Required (NPSHr) on pumps, etc.

Mounted without restriction at the highest part of a piping system, expansion tanks should remain uninsulated as the tanks should not be subjected to fluid at elevated temperatures.

Depending on the application, these tanks can be designed to meet ASME or Non-ASME code requirements. Choose from a number of pre-engineered models shown below or consider a custom tank that can be properly sized and manufactured based on specific application requirements.

| Model Number | description | equipment category | expansion tank available | Learn More |

|---|---|---|---|---|

| TNKS-00001 | Pre-Engineered expansion tank equipped with a liquid level sight glass and low-level switch. ASME B31 carbon steel piping materials, welded construction, built to ASME standards, and pre-drilled mounting holes for quick installation. | Pre-Engineered | 18 Gallon | Details |

| TNKS-00002 | Pre-Engineered expansion tank equipped with a liquid level sight glass and low-level switch. ASME B31 carbon steel piping materials, welded construction, built to ASME standards, and pre-drilled mounting holes for quick installation. | Pre-Engineered | 30 Gallon | Details |

| TNKS-00003 | Pre-Engineered expansion tank equipped with a liquid level sight glass and low-level switch. ASME B31 carbon steel piping materials, welded construction, built to ASME standards, and pre-drilled mounting holes for quick installation. | Pre-Engineered | 40 Gallon | Details |

| TNKS-00004 | Pre-Engineered expansion tank equipped with a liquid level sight glass and low-level switch. ASME B31 carbon steel piping materials, welded construction, built to ASME standards, and pre-drilled mounting holes for quick installation. | Pre-Engineered | 60 Gallon | Details |

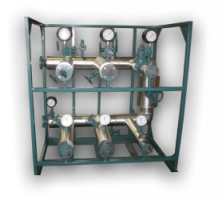

Custom Engineered Tanks

For custom designs, HEAT offers four distinct levels of customization, ranging from minimal customization to fully built-to-specification designs. Each unique system undergoes a Factory Acceptance Test in accordance with HEAT standard practice prior to shipment.

- General Purpose and Hazardous Area Designs

- Designed for thermal fluid or water/water-glycol fluids

- Pre-Drilled Mounting Legs Available

- Custom Designs allow (4) Levels of Customization

- Indoor/Outdoor installation

- Mounting Legs Available

- Vertical or Horizontal Tank Orientations

- Sight glass or level Indicator

- Level switches available

- ASME Design and Stamp Available

- Seller standard or Custom Paint Colors

- Welded and flanged construction

- Carbon steel and stainless steel available

- ASME B31 Piping Materials

- ASME U/UM, CRN

- MINIMAL - CATEGORY 1: REFERENCE ONLY

- Drawings are supplied for reference as our engineering team completes the design and your system is fabricated

- MODERATE - CATEGORY 2: DRAWING APPROVAL

- Drawings are sent for your approval before fabrication begins

- HIGH - CATEGORY 3: FULL APPROVAL

- High level of input into drawings and components, with approval at every phase

- COMPLETE - CATEGORY 4: BUILT-TO-SPECIFICATION AND FULL APPROVAL

- Complete input to meet your plant specifications, required submittal documentation, and/or preferred brand of components. Approval at every phase.

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.