Thermal Fluid Systems for Textiles, Fabrics, & Nonwovens

The Textiles, Fabrics & Nonwovens industry has always required dependable reliability from its processes to achieve high-volume production. Modern advancements in the market have introduced the need to rapidly change materials, features, or designs while maintaining volume and product quality.

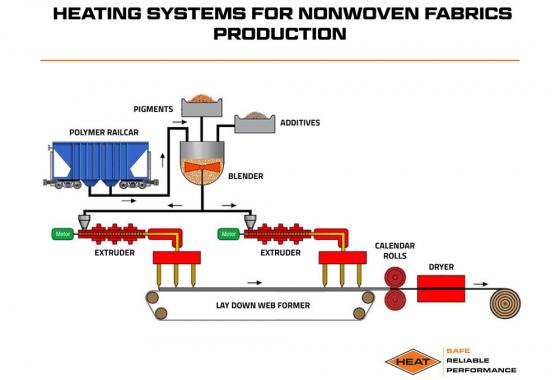

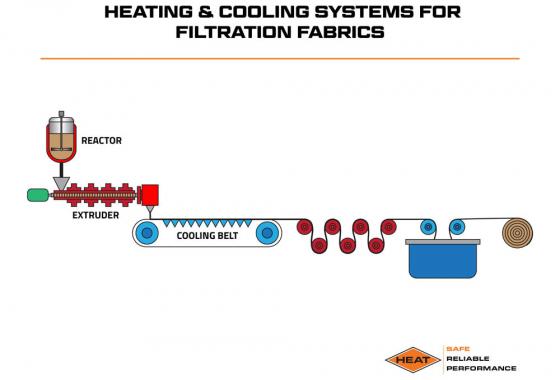

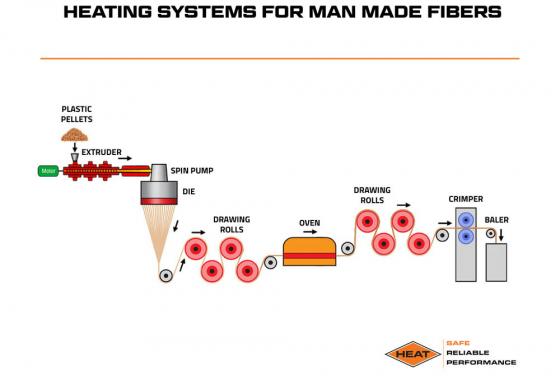

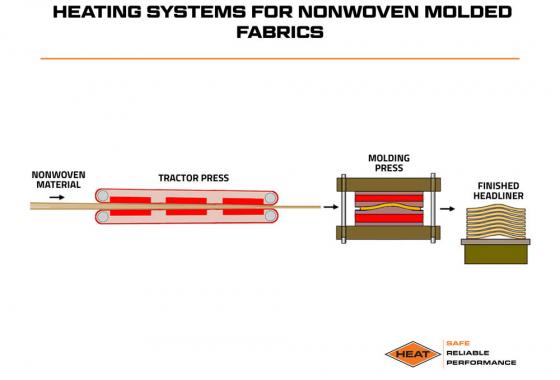

A critical part of maintaining the quality of these products is temperature control during the manufacturing process. HEAT has worked frequently with our customers to develop unique temperature control solutions that deliver our signature Safe Reliable Performance. Our experience includes designing custom solutions for these applications:

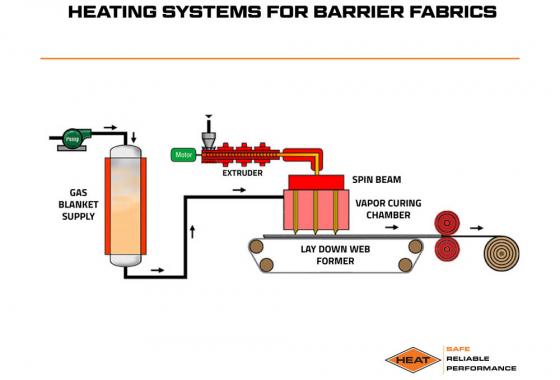

- Barrier Fabrics Production

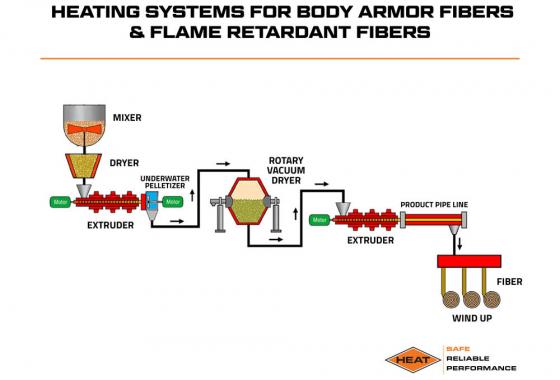

- Body Armor Fibers Production

- Flame Retardant Fiber Production

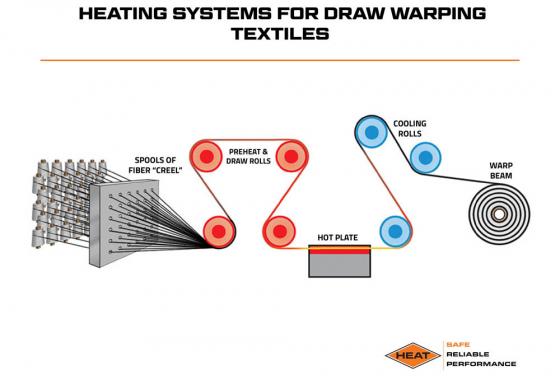

- Draw Warping Textiles

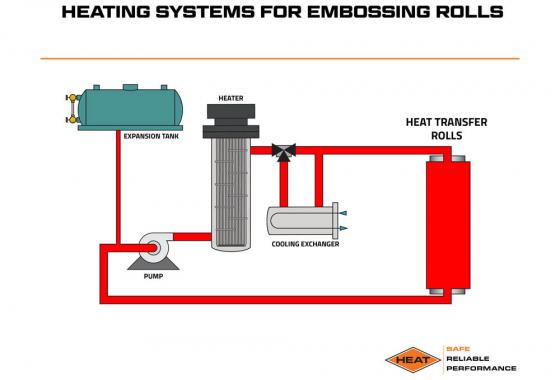

- Embossing Rolls

- Nonwoven Fabrics Production

- Filtration Fabrics Production

- Man Made Fiber Manufacturing

- Nonwoven Molded Fabrics

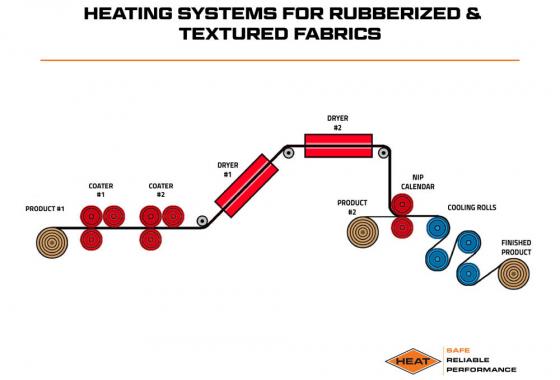

- Rubberized & Textured Fabrics Production

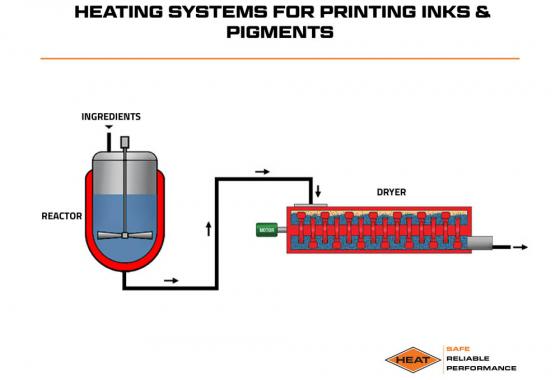

- Printing Inks & Pigments Production

Contact us today to request your custom temperature control solution or scroll through the application gallery below to learn more about our expertise.

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.