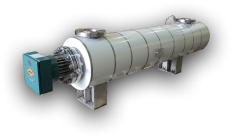

Electric Process Circulation Heaters

Heater design is a critical factor – two heaters of seemingly the same flange size and wattage will have different watt densities and aren’t necessarily interchangeable. Making this mistake could lead to costly repairs as your thermal fluid is damaged or destroyed. Other important considerations include variable process flow rates and sensitive thermal fluids. Don’t worry— HEAT is an industry expert with more than 100 years of combined experience designing heat transfer systems. Our Sales Engineers will help you choose the process circulation heater that is best for you.

What Kind of Circulation Process Heaters are there?

HEAT offers electric circulation process heaters both as stand-alone heater & chamber combinations or with control panels as skid-mounted circulation heater packages. A stand-alone circulation heater can be mounted either horizontally or vertically in line with your process piping, keeping the footprint small with controls elsewhere. A circulation heater package integrates a heater and a control panel, supplied with PID Loop Algorithm control and additional safety interlocks. All of this is mounted on a drip-proof, seal-welded plate-and-channel fluid containment base, creating a convenient all-in-one package to add a circulation heater to your process.

Electric Circulation Heater Capabilities

Electric Process Circulation Heaters work by heating fluid directly in the flow of process piping – a liquid or a gas flows through heating elements and is heated in a single pass before continuing on to the process. The heater’s internal baffles create turbulent flow across the heating elements, making sure that the fluid is heated evenly and with nearly 100% efficiency. Electric Process Circulation heaters can operate in temperatures up to 1200°F.

HEAT’s circulation heaters are all built with a thermocouple sensing the temperature directly at the sheath of a heating element. This allows for minimal temperature overshoot when paired with a control panel and provides over-temperature protection for the heater and the fluid being heated.

Customized Electric Circulation Heaters

Customizations are offered in 4 different levels of our custom design process, all with a dedicated project manager. If you need help with installation, maintenance, or spare parts down the line, our dedicated Service and Aftermarket teams have your back.

Learn more about Electric Circulation Process Heaters and Circulation Heater Packages below.

- Asphalt Heating

- Tank Heating

- Air Heating

- Nitrogen Heating

- Process Gas Heating

- Thermal Fluid Heating

- Water / Water-Glycol Heating

Electric Circulation Heaters are commonly found in these industries:

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.