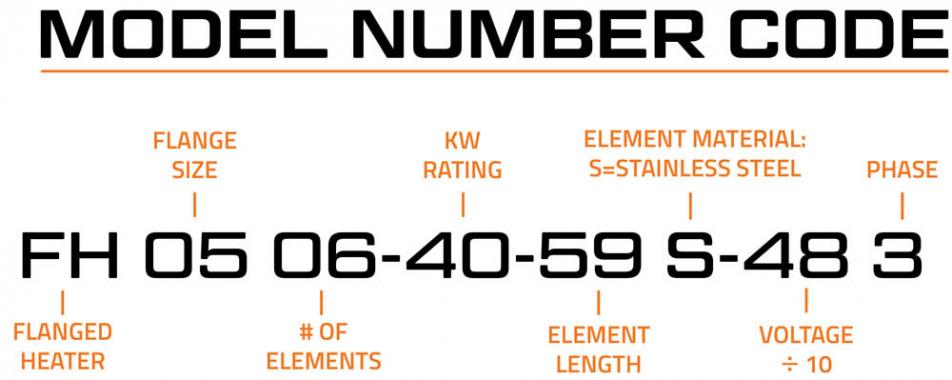

Flanged Immersion Heaters

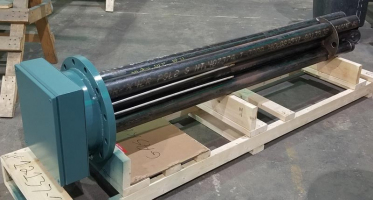

FH Series Flanged Immersion Heaters consist of a number of "U" bend tubular heating elements welded into a standard ANSI pipe flange. Elements are supported with TEMA-style baffles. A thermowell is installed through the center of the flange for the over-temperature sensor.

Flanged Immersion Heaters are easily installed by direct mounting to a tank, pipe, or vessel through a mating flanged nozzle. Each of our electric immersion heaters is shipped with a spiral wound mounting gasket.

Flanged Immersion Heater Capabilities

Flanged immersion heaters are provided with a NEMA-rated enclosure to protect the heater element terminations and pre-bussed circuitry. The standard enclosure allows for the customer to locate conduit knock-outs as required for field wiring.

Our electric immersion heater designs are capable of heating water, air, steam, gas, light oils, heavy oils, thermal fluids, and chemicals. Maximum design temperature is 1,200°F, depending on the medium being heated.

Customized Flanged Immersion Heaters

HEAT offers four distinct levels of customization, ranging from minimal customization to fully built-to-specification designs. Each unique system undergoes a Factory Acceptance Test per HEAT standard practice before shipment.

- Designs to 480kW and Higher

- Temperatures up to 1,200°F

- 5", 6", 8" 10", 12" and 14" flange sizes available

- 150, 300, 400 or 600 lb. ANSI flanges

- 208 volt through 575 volt, 3 phase

- Watt Densities from 5 to 40 watts/In²

- 4 Levels of Customization

- Stainless-Steel Sheathed Elements

- Nickel Plated Copper Bussing

- Baffles provide Increased heat transfer and structural support to elements

- NEMA 12, 4, 4X, 7 terminal housings available

- Thermowell for high temperature limit sensor

- 48 Amp maximum per circuit

- ASME Code stamp available

- Moisture Seal on each Element

- Long life - 2 year warranty

Related Categories

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.