Custom Engineered Gas Fired Heating

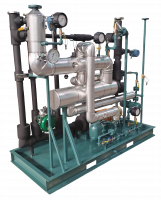

GFW Series Custom Engineered Water/Water-Glycol Heat Transfer Systems offer Safe Reliable Performance in industrial gas-fired hot water systems with large heating capacity.

Commonly used with satellite DIW Series Systems or EMW Series Systems, GFW Series systems provide a central water/water-glycol thermal fluid heating source for control of multiple, independent zones.

Our engineering team will work with you to design a system based on your unique process or application. GFW Series systems typically include a Pump, Heater or Boiler, Cooling Circuit, Expansion Tank & Control Panel. Designs are capable of maximum operating temperatures up to 400°F and heating capacities up to 5.4 MM BTU/Hr.

GFW Series Systems are constructed of threaded or all-welded Carbon Steel, are insulated with Non-Wicking Cellular Glass, Fiberglass, Rubber, or Mineral Wool Insulation, and assembled on a drip-proof, seal-welded plate-and-channel fluid containment base.

HEAT offers four distinct levels of customization, ranging from minimal customization to fully built-to-specification designs. Each unique system undergoes a Factory Acceptance Test in accordance with HEAT standard practice prior to shipment.

- Maximum Operating Temperatures up to 400°F

- Heating Capacities from 300,000 Btu/hr. to 6.8MM Btu/hr.

- Up to 575 VAC, 3-Phase, 50/60Hz Power Capabilities

- Multi-Pass Water Coil Design

- General Purpose and Hazardous Area Designs

- Designs Temperatures of 250°F, 300°F and 400°F

- 4 Levels of Customization

- Indoor/Outdoor Installation

- Heat Only & Heat/Cool Designs Available

- Easy to Maintain

- Seller Standard or Custom Paint Colors

- Centrifugal Style

- Mechanical Seal Design

- Single and Dual Pump Configurations

- Vertical Orientation

- Multi-Pass, Staggered Coil Configuration

- ASME Boiler Code Construction

- Fully Modulating Output

- Capable of Meeting Low NOx Regulations

- High-Efficiency Design

- Integral and Modular Designs

- TEMA / ASME Exchanger Designs Available

- Air-to-Water, Water-to-Water, and Direct Inject Cooling Options Available

- Proportional and On/Off Control

- Top Mounted and Remote Mounted Designs

- Single and Double Expansion Line Designs

- Non-Pressurized and Pressurized Configurations

- ASME U/UM Designs Available

- NPT, Welded and Flanged Construction

- Carbon Steel and Stainless Steel Available

- ASME B31 Piping Materials

- Skid Mounted and Remote Mounted Control Panels

- Burner Management System

- Digital PID Temperature Control or Remote Operation Control

- Configurations for External Control from PLC, DCS or other External Control

- NEMA 4, NEMA 4X, NEMA 12, NEMA 7, and Class I, Division 2

- ASME, ASME B31.3, TEMA

- NFP70, NFPA 79, NEC, UL, cUL, CSA

- MINIMAL - CATEGORY 1: REFERENCE ONLY

- Drawings are supplied for reference as our engineering team completes the design and your system is fabricated

- MODERATE - CATEGORY 2: DRAWING APPROVAL

- Drawings are sent for your approval before fabrication begins

- HIGH - CATEGORY 3: FULL APPROVAL

- High level of input into drawings and components, with approval at every phase

- COMPLETE - CATEGORY 4: BUILT-TO-SPECIFICATION AND FULL APPROVAL

- Complete input to meet your plant specifications, required submittal documentation, and/or preferred brand of components. Approval at every phase.

Heat Systems: Safe by Design

Learn more about our Standard Design Practices for Custom-Engineered Hot Water/Water-Glycol Systems

Learn MoreRelated Categories

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.