Water-Glycol Heating Systems

HEAT is an industry expert with more than 100-years combined experience designing water & glycol heat transfer systems—our Sales Engineers will help you choose the water & glycol heating system that is best for you. Depending on your needs, one of our Pre-Engineered Systems could help meet your time sensitive demands, or a fully custom water & glycol system that incorporates the additional control and safety features your process requires will be the best solution. Custom designs can incorporate your available utilities (electric, natural gas, steam, central plant hot oil loops, etc.) and are offered at 4 different levels of our custom design process, all with a dedicated project manager.

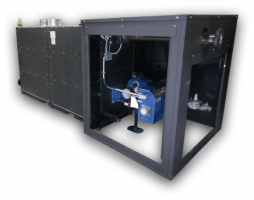

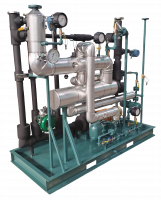

Closed-Loop Water Heating System

At their core, Glycol Heating Systems work by circulating heated water or a water/glycol mixture through a closed-loop piping circuit. This circulating fluid allows for the transfer of energy from a source to a product or process (heating), and also sometimes for transferring that energy away (cooling).

Water & Glycol Heating systems give you precise control of temperatures in a batch or continuous process and can operate at temperatures higher than steam (up to 350°F in some designs) with lower pressures, meaning no boiler attendant is needed.

What is the best heat transfer media?

Based on its physical properties, water is the best heat transfer media. However, water has limitations as it nears freezing or boiling.

An ethylene glycol or propylene glycol mixture will lower the freezing point and raise the boiling point of fluid inside a heat transfer system, but this also influences the fluid’s heat transfer properties.

The choice of whether to use water or a water-glycol mixture as the heat transfer fluid depends on your process and industry needs. Contact our experts to learn more about what is best for you.

Are Water Glycol Heating Systems Safe?

Safety is HEAT's highest priority: all our designs are built to exacting codes and standards. Piping connections are all-welded, flanged, or threaded and insulated with fiberglass, rubber, or non-wicking cellular glass insulation. Every system is rigorously tested during our Factory Acceptance Test process, which you can witness in person or virtually. Our Service and Aftermarket teams are dedicated to providing you with on-site equipment start-up assistance, training, troubleshooting, and spare parts support. We also offer preventative maintenance and fluid care help to keep your system running safely and at peak performance.

We divide our water & glycol heating system designs into categories based on the heat source. Learn more below!

- Tanks

- Jacketed Tank / Vessel

- Reactor Vessel

- Platens / Presses

- Ovens

- Jacketed Piping

- Rolls (Calendar, Nip, etc.)

- Autoclaves

- Conveyors / Screw Conveyors

- Molds / Dies

Glycol Heating Systems are commonly found in these industries:

Contact Our Experts

Our expert sales engineers can help you find the right custom temperature control equipment for your application.

*denotes a required field.